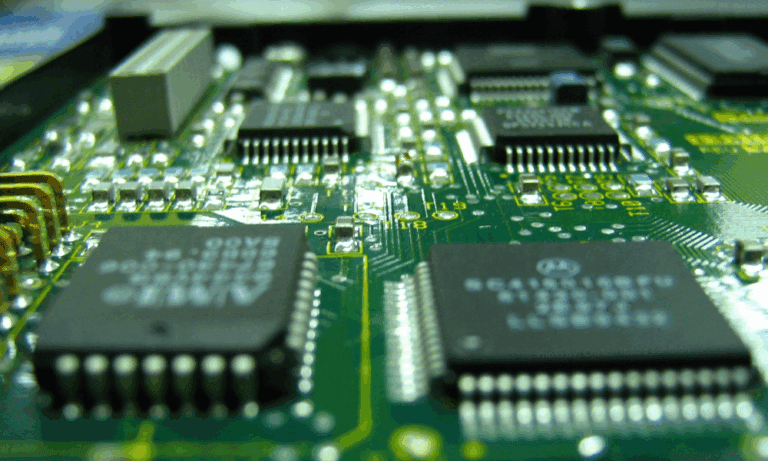

Invisible signals surround us: Wi-Fi, Bluetooth, cellular, GPS, and more. Every time a new device comes online, it adds to this noise. Most people only notice these signals when there’s a problem. However, this ambient electromagnetic interference (EMI) can be a form of silent sabotage for engineers testing electronic prototypes.

Ambient EMI can distort test data, create false problems, and conceal real issues. This makes it harder for engineers to diagnose design flaws early, potentially leading to costly failures in formal compliance testing later. Without proper shielding, engineers are relying on unreliable data, creating an uphill battle for any engineering team.

Fortunately, a properly shielded electromagnetic interference enclosure—often made from aluminum due to its natural shielding properties—will isolate your electronic prototype design from external signals. Electromagnetic interference shielding establishes a controlled test environment so engineers can gain reliable insights, reduce false readings, and catch compliance issues before they become expensive redesigns.

Electromagnetic Interference: The Basics

Electromagnetic interference is unwanted electrical noise that disrupts the performance of electronic circuits. It originates from natural and manmade sources and can distort signals and degrade measurements.

EMI is everywhere. Common external sources include nearby cell towers, Wi-Fi routers, Bluetooth devices, switching power supplies, and even LED lighting. All can radiate or conduct noise into a prototype, especially when testing is done without proper shielding. EMI can couple into a system through several mechanisms:

- Conduction: noise enters through power or signal lines.

- Radiation: signals travel through the air and couple into nearby circuits.

- Capacitive: interference transfers between conductors that are close together but not touching, such as adjacent signals on a circuit board.

- Inductive: changing electrical currents create magnetic fields that unintentionally induce a voltage in nearby wires or circuits.

These coupling paths are particularly problematic during early testing, before filtering, shielding, and layout optimization are finalized. Without EMI control measures like shielded enclosures, engineers may misinterpret or completely miss design flaws, leading to flawed data and failed compliance tests.

Prototype Evaluation: An EMI Shielded Enclosure Raises Confidence

A well-designed EMI shielded enclosure can make all the difference. Isolating an electronic prototype design from external interference creates a controlled environment that supports accurate, repeatable evaluation. Key benefits include:

Eliminating False Reports

A well-designed EMI shielded enclosure creates a controlled evaluation environment. By isolating a device from ambient noise, shielding eliminates false positives and negatives. Engineers can be confident that test results reflect the prototype’s actual behavior.

Producing Repeatable Results

Shielding also enables repeatable, apples-to-apples testing between hardware revisions, firmware versions, or configuration changes. With outside variables removed, developers gain a clear baseline for comparisons, allowing them to detect subtle improvements (or regressions).

Shortening Debug Cycles

Shielding can help shorten debug cycles. Without the distractions caused by EMI, engineers can focus on identifying real design flaws, not chasing phantom bugs. That clarity saves time, reduces unnecessary revisions, and accelerates progress toward a compliant, production-ready design.

EMC Compliance Testing

Developers must meet strict electromagnetic compatibility (EMC) requirements to ensure their designs don’t emit too much electromagnetic interference and are not overly sensitive to EMI from other sources. Proper electromagnetic interference shielding plays an important role in EMC compliance testing. When prototypes are evaluated in shielded environments, they are more likely to reveal problematic emissions or susceptibility issues before formal testing. By catching EMI problems during early evaluations, teams can avoid costly redesigns and delays, ensuring a smoother path to certification and market launch.

Why Aluminum Enclosures Shine

When developing electronic prototypes, achieving effective electromagnetic interference shielding without inflating costs can be a significant challenge. Lansing Instrument Corp. addresses this need with their aluminum enclosures, which offer inherent EMI and radio frequency interference (RFI) shielding. Aluminum naturally provides extensive signal reduction across a broad frequency range, often eliminating the need for additional treatments.

Lansing Instrument Corp. offers two families of aluminum electronic enclosures, GrayBox and MicroPak. These enclosures are available in various sizes, from handheld units to rack-mounted systems. This flexibility enables teams to prototype and iterate efficiently, adapting to different project requirements.

Moreover, aluminum’s machinability facilitates the addition of custom cutouts for displays, connectors, and mounting hardware. Lansing offers tailoring services to ensure enclosures are configured to meet the specific requirements of each application.

By combining effective EMI shielding, affordability, and scalability, Lansing’s aluminum enclosures provide a practical solution for cost-conscious prototyping.

Proper electromagnetic interference shielding during prototype evaluation isn’t just good practice—it’s essential. It helps teams work smarter, iterate faster, and avoid costly surprises. Whether you’re building your first prototype or refining a next-gen design, Lansing helps you test with confidence. Discover how Lansing’s aluminum enclosures and shielding solutions can support your next project.