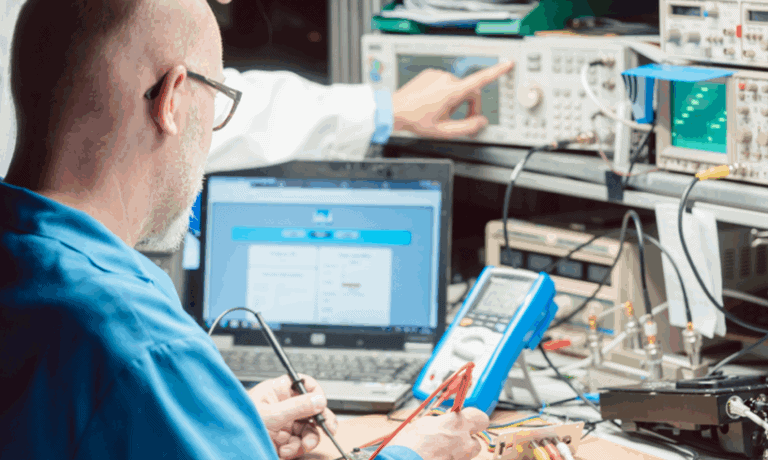

Speed and precision are key in product development. For companies building sophisticated electronics, especially in MedTech, laboratories, and equipment manufacturing, getting to market quickly isn’t enough. The product must also function flawlessly, comply with industry regulations, and withstand real-world conditions.

That’s why choosing the right electronic enclosure for your prototype early in the design process is essential.

Far from being just a final shell that holds the electronics together, the electronic enclosureplays an active role in development. It enables testing, improves performance, and supports compliance from day one. When used effectively, enclosures help teams identify and address challenges early, before they become costly redesigns. Here’s how prototype electronic enclosures are an important part of the electronic enclosure process:

Why Enclosures Aren’t Just for the Final Product

Many development teams overlook the importance of enclosures during prototype development, focusing instead on the internal electronics. But enclosures aren’t just containers; they’re also critical design elements. A custom electronic enclosure, or an adaptable off-the-shelf solution, provides a way to test how a product performs in real-world settings.

For example, enclosures provide protection against dust, moisture, and impact during field testing, while also allowing for validation of key design elements like ventilation, board layout, and cable access. This means that decisions about enclosure design can be evaluated early in the process, leading to increased product quality, enhanced performance, and faster certification timelines.

Material Testing: Know Your Limits Early

Material selection is a central concern in prototyping. The right electronic enclosure allows engineers to test how materials respond to heat, vibration, and electromagnetic interference. This is especially important when compliance with EMI/RFI standards or environmental sealing is required.

Using prototype electronic enclosures early in the design process lets teams evaluate how well the housing supports thermal management, dissipates heat, and maintains structural integrity. Testing these features at the prototype stage reduces the risk of failure during later phases or post-launch.

Accelerate Iteration: Designed for Development

Prototype enclosures allow you to test multiple designs at once, speeding up the enclosure’s development process timeline. For example, you might choose an enclosure with removable panels, modular compartments, or customizable openings. Evaluating each prototype against one another can improve your product development cycle and make testing and approval more efficient.

At Lansing Instrument Corp, we offer a wide range of enclosures designed with development in mind. These housings make it easier for teams to swap out components, adjust layouts, and reconfigure designs without starting from scratch.

Designing with Compliance in Mind

Waiting until the final product stage to consider compliance is a common and costly mistake. Prototyping with the right enclosure helps address compliance factors like EMI shielding, IP ratings, and thermal performance upfront.

Configuring enclosures for performance and design reduces the chance of needing significant design changes later. Whether your product will face strict MedTech regulations or harsh industrial environments, designing with compliance in mind from day one saves time and money.

Off-the-Shelf Designs: Weighing the Options

When speed is critical, off-the-shelf enclosures can offer a fast and cost-effective solution. These project boxes are ideal for proof-of-concept builds and early-stage prototyping, especially when modified to support testing needs.

Still, off-the-shelf enclosures may not provide the precise dimensions, mounting options, or shielding needed for advanced designs. As the product nears production, transitioning to a custom electronic enclosure ensures optimal fit, performance, and branding.

Lansing Instrument’s standard and custom enclosures ensure you’ll have the most options when prototyping your designs.

Saving Time and Reducing Redesign Cycles

Prototyping with the right enclosure reduces guesswork and rework. By validating thermal, mechanical, and environmental aspects early, you avoid late-stage surprises that delay launches and inflate budgets.

Whether you’re conducting lab testing, building a field-ready prototype, or prepping for compliance audits, the enclosure should support your development workflow. Lansing Instrument’s enclosures are engineered with iteration in mind, giving teams the flexibility to explore, adapt, and refine with confidence.

Partner with Experts in Electronic Enclosure Prototype Development

At Lansing Instrument, we understand the demands of product development. Our high-quality electrical enclosures are trusted across industries for their quality, performance, and adaptability.

Whether you’re working on a MedTech device, a laboratory instrument, or equipment manufacturing, we’re here to help you accelerate development with enclosure solutions that will fit your specific needs. Want to learn more about how to create a custom electronic enclosure prototype? Contact Lansing Instrument today to find out how we can help.