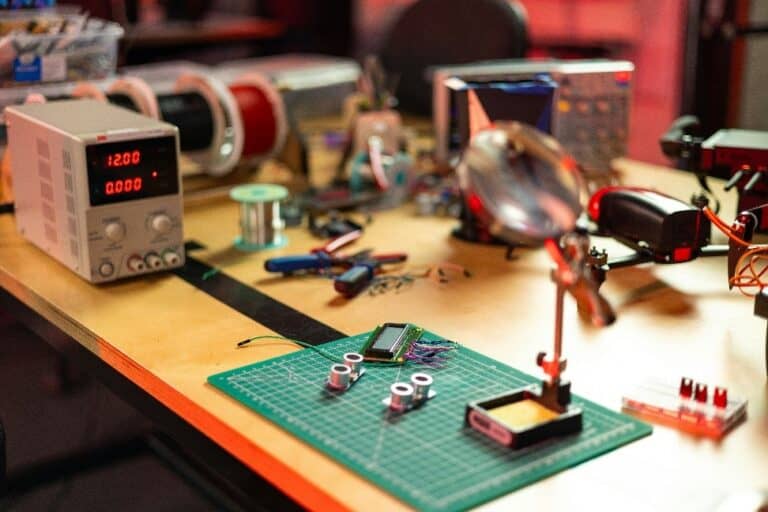

Early-stage product development isn’t about getting everything right the first time. When engineers, researchers, and innovators begin the journey from concept to reality, they’re focused on learning fast, iterating quickly, and adapting on the fly. Electronic enclosures don’t just house electronics – they help protect, organize, and enable real-world testing.

Choosing the right electronic project box early can mean fewer delays, faster adjustments, and more reliable results. So, what should you look for when selecting a project box for prototyping?

The Importance of Enclosure Selection in Prototyping

While prototyping is all about iteration, the foundation still needs to be sound. A thoughtfully selected electronic project box can help ensure electrical safety, maintain signal integrity, and provide consistent structural support as designs evolve. It goes beyond housing the hardware to create a stable, test-friendly environment that enables repeatable results and reduces noise, risk, and rework. Explore the role that smart enclosure design plays in supporting successful prototyping.

The Key Components of a Good Project Box Enclosure

Designing for Iteration, Not Perfection

No two projects look alike, and the same is true for most enclosures. Each project has its own set of requirements and poses unique challenges. When selecting an electronic project box, it’s easy to get pulled into production-level considerations too soon. While final products demand polished aesthetics, regulatory compliance, and robust environmental protections, your electrical project box for prototyping should prioritize ease of access, modification, and adaptability. The most effective enclosures during R&D prototyping are the ones that:

- Are structurally sound and safe for internal components

- Let you open, modify, and rewire without hassle

- Have internal room for layout changes

- Can support evolving port and interface needs

- Help you move from idea to data collection faster

- Can be reused

These characteristics are often overlooked in favor of long-term specs but are essential in the “test and tweak” stages.

Think of your next R&D project as a puzzle with all the pieces already included, but you’re unsure of where they’ll all fit when the project is completed. This is where Lansing’s electronic instrument enclosures excel. You can start with a basic enclosure, add to it, adapt it, and transform it as your project’s needs change.

1. Modification is the foundation of any prototype

The last thing you want prototyping your newest idea is to be constrained by your enclosure. A good electrical project box is adaptable, no matter how big the design changes are.

Lansing offers GrayBox enclosures in three different styles and 81 standard sizes to help you find the best box for your R&D project. In addition, MicroPak enclosures are perfect for small-scale applications, without compromising durability and flexibility, and are modifiable in 18 different sizes.

Here’s how Lansing’s modifiable project box enclosures can help speed up your prototyping:

- Flexible layout: Panels, covers, accessories, and cutouts that can be swapped out or repositioned

- Universal mounting options: Internal rails or plates for boards

- Varying mounting styles: Freestanding, wall-mounted, or rack-mounted

- Environment variation: Materials and finishes that provide value and longevity no matter the environment

A modifiable enclosure gives you the freedom to adapt your design, layout, and internal components as you work through prototype phases. This freedom to add or subtract enclosure elements throughout the design process helps ensure you’ll meet deadlines and effortlessly adapt to any new requirements.

2. Select an electronic instrument box that’s reusable

In R&D, designs evolve, components shift, and new needs emerge with every test cycle. A reusable enclosure is built to accommodate that reality. Not only will you be able to pick and choose your layout and components, but you can add and subtract them as needed. Then, when the next project begins, your reusable enclosure will have all the components you need to adapt to the next project’s requirements without starting from scratch.

With Lansing’s durable aluminum electronic enclosures, you’ll be able to use and reuse your electronic project boxes over and over again, making them ideal for prototyping any electrical project.

3. The right enclosure allows you to edit and adapt with speed

Design changes are at the core of prototyping. Your chosen enclosure should support iterative workflows that place the control in your hands so you can make changes and updates as needed. Not only is that a cost-effective strategy, but it gives you the freedom to make layout edits in real time as ideas and needs change.

Lansing’s electrical project boxes are designed with this flexibility in mind, making them ideal for lab environments and R&D projects where speed and adaptability are critical. With 6 styles, 135 standard sizes, and dozens of height and width dimensions, there are 1000s of variations available to help you build the high-quality enclosure you need, piece by piece, without the price tag of a custom enclosure.

Take the Next Step in Smarter Prototyping

If you’re ready to build faster, test more freely, and accelerate your path from idea to prototype, Lansing is here to help with electrical project boxes that can be modified and adapted as little or as much as you need. Lansing offers a full lineup of flexible, modifiable, and reusable enclosures that meet the needs of R&D teams across industries – from labs to equipment manufacturers.

Browse Lansing’s electronic enclosures to find the right project box enclosure for your needs or connect with the support team directly to discuss your prototyping goals and get personalized recommendations.