When you’re designing sensitive equipment, whether it’s medical devices, laboratory instrumentation, or advanced automation systems, thermal management can’t be an afterthought. Heat buildup inside instrumentation enclosures can shorten component life, lead to sensor drift, and trigger downtime that no engineer wants. Choosing the correct enclosure material and the cooling strategy that follows can make the difference between stable long-term performance and a series of costly setbacks.

That’s where aluminum shines. With its high thermal conductivity, aluminum provides a natural platform for both passive and active thermal management strategies. Let’s explore why this matters, how passive and active cooling works, and why aluminum instrument enclosures offer a reliable foundation from prototype to production.

Why Aluminum Is Ideal for Thermal Management

Enclosure materials like steel, plastic, and aluminum each have their own benefits and tradeoffs that can affect the cost of a project, the durability of components, and the overall thermal behavior of an instrument enclosure. Here are just a few key aspects of each:

- Steel: Strong and durable, but also heavy, which can make shipping, installation, and maintenance costs higher. Without the proper coating or treatment, standard carbon steel is also susceptible to rust and corrosion. Importantly, steel’s thermal conductivity is low (~50 W/m·K), leaving components vulnerable to hot spots.

- Plastics and composites: Lightweight and inexpensive, but the enclosures become weakened over time, particularly when exposed to high heat. Because of plastic’s poor thermal conductivity (<1 W/m·K), heat can build up rapidly without supplemental cooling.

- Aluminum: Strikes a balance between steel and plastic because it’s lightweight, machinable, corrosion-resistant, and is a natural thermal conductor (~200 W/m·K). This makes it uniquely suited for enclosures where heat must be managed efficiently.

When you’re in the beginning stages of a project, it’s important to start with the right material first, before moving on to more complex prototyping and designs. With aluminum instrumentation enclosures, you’ll ensure that your equipment and internal components have the most adaptable thermal environment, whether you’re designing for MedTech projects, labs, or network and power applications.

The Benefits of Passive Thermal Management Systems

Aluminum’s high thermal conductivity makes it an ideal material for passive heat management, but you can further enhance heat dissipation through fins and integrated heat sinks. Fins increase the surface area exposed to air, accelerating heat transfer, while heat sinks – either internal or attached to high-heat components – draw heat away from sensitive electronics and distribute it evenly.

Ventilation and coatings add additional layers of passive cooling. Properly positioned vents encourage natural airflow, allowing warm air to escape and cooler air to circulate around internal components. Specialized thermal coatings on aluminum surfaces can boost emissivity, helping the enclosure radiate heat more efficiently, while also providing corrosion resistance and environmental protection.

The payoff of these passive systems is significant. Enclosures remain cooler, electronics operate more reliably, and overall system longevity improves – all without the complexity, noise, or failure risks associated with active cooling solutions.

Scaling Projects to Active Thermal Management Solutions

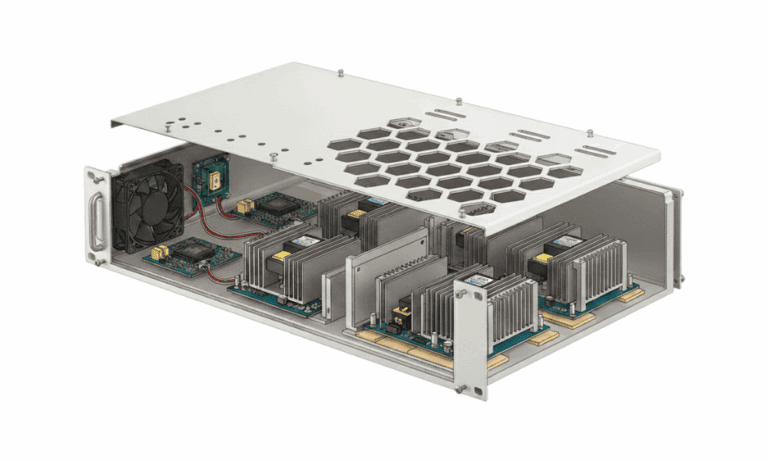

Of course, not every system can get by with passive cooling alone. Active thermal management takes aluminum instrumentation enclosures beyond passive heat dissipation by incorporating powered systems that actively move and control heat. Internal circulation fans are often the first line of defense, improving airflow inside the enclosure, eliminating hot spots, and creating more uniform temperatures across components.

For higher-performance applications, aluminum enclosures serve as a stable platform for heat exchangers, vortex coolers, or even integrated air conditioning units. These systems rely on the enclosure’s structure to mount components securely while providing efficient thermal interfaces that transfer heat away from critical electronics.

Aluminum itself enhances active cooling performance. Its natural ability to distribute and radiate heat evenly reduces thermal stress on fans, pumps, and heat exchangers, allowing active systems to operate more efficiently and extend the lifespan of both the enclosure and its components. The result is precise, reliable thermal control: aluminum-based enclosures with active systems maintain consistent operating temperatures, prevent overheating under heavy loads, and support high-performance electronics in demanding environments.

From Prototype to Presentation: Why Aluminum Instrumentation Enclosures Are the Best Option

Aluminum enclosures give engineers a scalable platform for both passive and active thermal management. A single design can accommodate varying passive or active thermal management, allowing you to manage development time and simplify the path from lab testing to full-scale deployment.

Reliability is another major advantage. Aluminum’s consistent thermal conductivity and structural stability ensure repeatable performance in sensitive MedTech devices, lab instruments, and automated systems, keeping components within safe temperature ranges and minimizing thermal-induced failures.

Aluminum’s versatility also bridges early-stage prototyping and production-grade systems. Simple passive solutions can evolve into active cooling strategies as requirements grow, all within the same enclosure footprint. From maintaining compliance and patient safety in MedTech to supporting maintenance-free lab experiments, or handling high-load networking and power systems, aluminum provides a durable, efficient, and adaptable thermal platform for a wide range of applications.

Browse Lansing’s instrument enclosure to find the best fit for your next project or connect with the support team directly to discuss your enclosure needs and get personalized recommendations.