Electronic systems are deployed in a wide range of environments, from sterile indoor labs to harsh outdoor settings. While performance and functionality often take center stage, one critical factor is sometimes overlooked: corrosion protection. Without it, even the most advanced electronics can fail, leading to costly repairs, downtime, or safety hazards. Electronic corrosion protection begins with choosing the right enclosure design to stand up to damaging conditions.

Common Corrosion Types in Electronics

Corrosion can happen to both metals and nonmetals when they undergo a chemical reaction with the surrounding environment, which results in a gradual degradation of the material. Factors such as humidity, salt, oxygen, and pollution often trigger these reactions. While various forms of corrosion can occur in electronics, several types are especially common:

- Atmospheric Corrosion: Caused by direct exposure to environmental elements like humidity, oxygen, air pollutants, and salts.

- Uniform Corrosion: Occurs evenly across a surface due to consistent exposure to moisture, oxygen, or other corrosive agents.

- Electrochemical (Galvanic) Corrosion: Happens when two dissimilar metals are in electrical contact in the presence of an electrolyte (such as water), causing one metal to corrode faster while the other is protected.

- Crevice Corrosion: Develops in confined spaces where moisture and contaminants become trapped, leading to localized, oxygen-deprived, or acidic conditions.

- Chemical Corrosion: Triggered by direct exposure to aggressive substances such as acids, alkalis, or solvents.

- Filiform Corrosion: Occurs when water penetrates beneath a protective coating on metal surfaces, leading to thread-like corrosion patterns.

Understanding which types of corrosion are most likely to occur in your device’s operating environment is key to choosing the right protective measures.

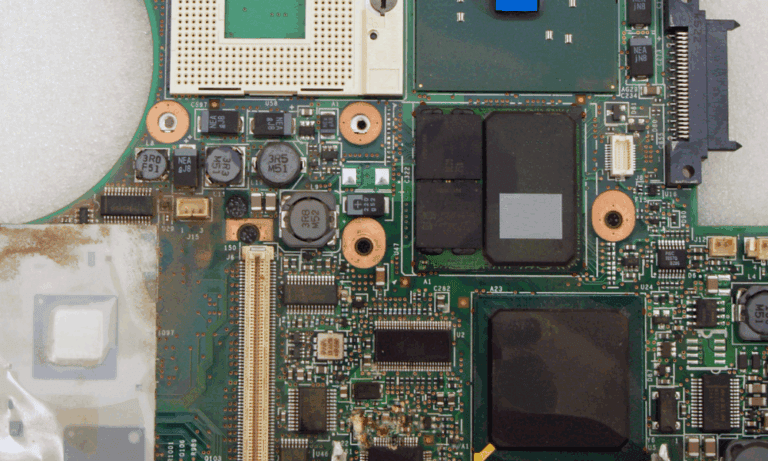

The Impact of Inadequate Electronic Corrosion Protection

Corrosion is more than a cosmetic concern—it can compromise performance, safety, and cost efficiency. Failing to invest in proper corrosion protection for electronic enclosures can lead to significant consequences, including:

Equipment Failure: Corroded enclosures may develop cracks, holes, or compromised seals, allowing moisture, dust, or debris to enter and damage internal components.

Operational Downtime: Corrosion-related failures often require unplanned maintenance or replacement of equipment, resulting in costly downtime and loss of productivity—especially in industrial and mission-critical environments.

Safety Risks: Deteriorated enclosures and exposed electronics can increase the risk of electrical hazards, including short circuits, electric shock, or fire.

Rising Long-Term Costs: Initial savings from using lower-cost or unprotected materials are often offset by recurring expenses for repairs, replacements, and labor, along with the hidden cost of interrupted operations.

Investing in corrosion-resistant materials and proper enclosure protection is essential to ensure equipment longevity, operational reliability, and workplace safety.

How to Choose a Corrosion-Resistant Enclosure

Choosing a corrosion-resistant enclosure isn’t just about picking a durable box – it requires considering operating environments and applications to select the right combination of material, coating, and design features.

Select the Right Material

Start by evaluating the environment where the enclosure will be used. Is it outdoors, in a coastal area, inside a chemical plant, or in a relatively clean indoor space?

Coastal or marine environments expose equipment to salt spray and high humidity, which are highly corrosive. Materials like stainless steel or fiberglass reinforced polyester (FRP) are ideal because they’re highly resistant to saltwater corrosion.

Industrial or chemical environments often involve exposure to acids or other harmful substances. Non-metallic materials like FRP or polycarbonate can resist chemical attacks.

Outdoor general-purpose settings need protection from rain, UV exposure, temperature changes, and pollution. Aluminum or stainless steel are reliable and weather-resistant choices.

Indoor or low-risk environments where moisture and contaminants are minimal, more economical materials like aluminum or polycarbonate are often sufficient.

Consider Protective Coatings to Extend Lifespan

Protective coatings play a crucial role in enhancing electronic corrosion protection for enclosures, especially when they’re made from metals like steel or aluminum. These coatings act as barriers between the metal and the environment, preventing moisture, oxygen, salts, and chemicals from causing corrosion. Common options include:

- Powder Coating: Durable and uniform. Great for: UV resistance and outdoor durability

- Anodizing: Enhances aluminum’s natural oxide layer. Great for: aluminum enclosures in outdoor, coastal, or industrial environments.

- Chromate: Converts the surface of a metal into a protective, corrosion-resistant film. Great for: applications requiring grounding or further painting

- Galvanizing: Adds a zinc layer that corrodes instead of the steel. Great for: highly corrosive environments, like industrial sites.

- Electrocoating: Provides thin, even coverage even in complex geometries. Great for: intricate designs needing uniform protection.

- Epoxy Coatings: Strong, chemical-resistant barrier. Great for: Corrosive indoor factories and labs.

Design Matters: Smart Features That Prevent Corrosion

Beyond materials and coatings, good design reduces corrosion risk:

Minimize water and dirt buildup

- Use angled tops or sloped surfaces

- Avoid horizontal lips or crevices

- Include drainage holes or weep paths

Control internal humidity

- Use vents that will allow airflow while blocking water and dust

- Place vents strategically to avoid water entry and promote air movement

Prevent small hardware from becoming weak points

- Use corrosion-resistant hinges, latches, and screws

- Avoid exposing threads to the environment

Ensure proper sealing

- Use continuous gaskets with lasting compression

- Choose gasket materials suited to the environment (e.g., silicone for heat)

- Design to meet appropriate IP or NEMA rating levels

Know the Enclosure Standards for Corrosion Resistance: IP and NEMA Ratings

Understanding enclosure safety ratings helps ensure you’re choosing the right protection level for your application.

IP Ratings (Ingress Protection – Standard IEC 60529)

IP ratings indicate how well an enclosure resists dust and water. While they don’t measure corrosion directly, higher ratings often mean better environmental sealing, which helps prevent corrosion by reducing moisture ingress.

Common IP Ratings for Corrosion-Prone Areas:

- IP65: Dust-tight, protected from water jets

- IP66: Strong protection from water and dust; ideal for outdoor use

- IP67: Withstands temporary immersion

- IP68: Withstands continuous submersion

NEMA Ratings (U.S. Standard)

NEMA ratings are mainly used in North America and offer broader protection categories-including resistance to corrosion, oil, ice, and more.

Relevant NEMA Ratings for Corrosion Resistance:

- NEMA 3R: Basic weather resistance

- NEMA 4: Watertight for indoor/outdoor use

- NEMA 4X: Like NEMA 4 but with added corrosion resistance-ideal for marine or chemical environments

- NEMA 6P: Submersible and corrosion-resistant-used in extreme conditions

Most of Lansing’s standard enclosures can be customized to meet NEMA or other weather ratings. Learn more here.

Corrosion-Resistant Enclosures from Lansing Instruments

Corrosion is one of the most overlooked threats, but its impact can be costly, hazardous, and disruptive. The good news is that with the right enclosure, it’s entirely preventable.

Lansing’s enclosures are inherently corrosion-resistant and suited to outdoor use thanks to their aluminum design. For additional protection, tailoring services are available for their standard GrayBox and MicroPak families, enabling you to create a custom enclosure specific to your needs.

By investing in corrosion protection upfront, you reduce long-term costs, improve safety, and ensure reliable performance over time. Explore Lansing’s line of electronic enclosures or contact our customer support team to get started.